ELGi EN Series Rotary Screw Air Compressor

4 to 20 HP configurations available, 5 year warranty, load-no load and VFD, includes start up at jobsite by ELGi trained factory technician.

- By ELGi

- Factory Warranty and Support Available

- Excluded From Free Shipping

- Local Service Available on All Brands

Overview

Features

- TEFC NEMA premium efficiency motor

- 4 to 20 HP options

- 13.1 to 81.5 CFM capacities (depending on selection)

- 100, 125, 150, 175 PSI options available

- Base or tank mounted models

- Tank mounted available with EGRD dryer or desiccant dryer with filters

- 60 gallon (4 to 7.5 HP) or 120 gallon (10 to 20 HP) tank options

- 100% rated duty cycle

- Variable speed drive option available (10 to 20 HP only)

- Auto belt tensioner of VFD models

- Impact and deceleration process oil separation

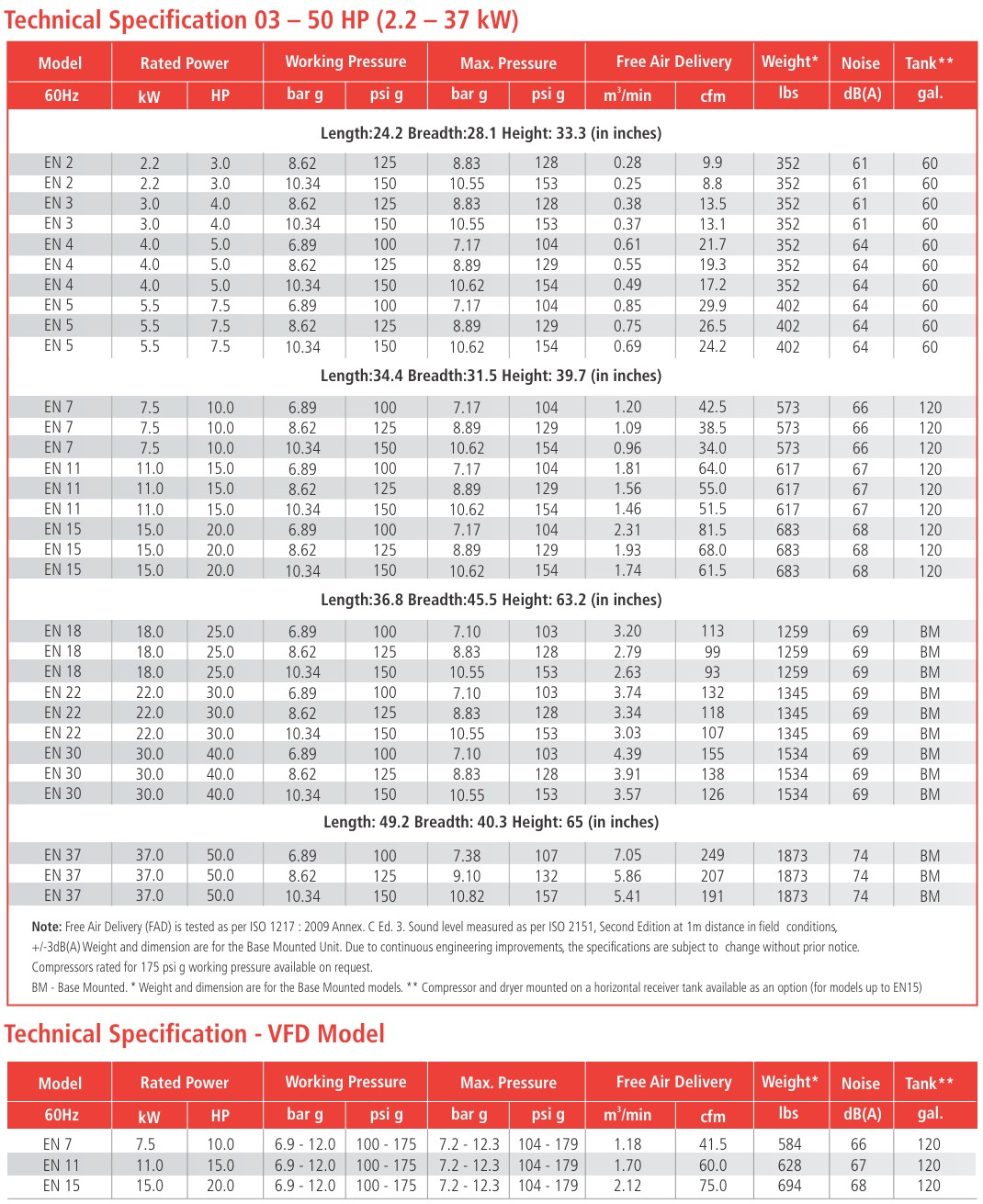

Tech Specs

Description

The ELGi EN Series rotary screw air compressor is designed to provide low carbon footprint along with high reliability and low maintenance requirements. The air filtration system keeps the compressor's internal components clean, maintaining optimum cooling efficiency and low oil-fill, resulting in a longer life span of the machine.

The EN Series features the Neuron XT controller which provides malfunction alarms, safety shutdowns, and easy-to-use service indications while allowing the user to monitor and control the machine's performance.

The EN Series air-oil separation utilizes the impact and deceleration process. The impact of the air-oil mixture in the circumferential tank area prompts deceleration action to remove the oil particles from the air. The air with minor traces of oil then enters the separator for further purification.

Documents

Accessories

Maintenance Kits

Lubricants

Warranties

Reviews

Reviews

Write a Review

-

Bye bye wet oily air

Reviewed on 11/25/2020Part Number: EN07-125-120T-G2AProblem solved. We needed more volume, no moisture, no oil. Compared all models and decided on the Elgi EN7-125 and could not be happier. Quiet, powerful and delivers perfect air. Our CNC sew machines are very happy now. The professional, helpful staff at Compressor World will help us keep this machine in top notch condition for years to come. No, it isn't inexpensive but down time and ruined equipment is far more expensive. Just buy it.- Good Air -

Got compressor Tuesday LOOKS GOOD

Reviewed on 9/9/2020Part Number: EN05-125-60T-G2AGot compressor Tuesday LOOKS GOOD- Pecan -

Fantastic Customer Service

Reviewed on 11/20/2019Part Number: EN15-125-120T-G2ACan not say enough about the support provided by Compressor World. We were having a bit of an oil leak problem with our new compressor and the team at Compressor World was there every step of the way to make sure that both ELGI and a local service company saw the problem taken care of. I was not expecting that from an online company. Their customer service is the best and will recommend them to everyone.- Carlos -

Perfect for Our Business

Reviewed on 11/15/2019Part Number: EN11-125-120T-G2AVery happy with our purchase of the ELGI compressor. Compressor World spoke so highly of the compressor and how that it is perfect for the granite business and they are right. Runs all of our machines with no problem and it is just so reliable that it fires up everyday. Very happy with Compressor World and will tell others about you as well. Thank you for following up.- Cris -

Run It 12 Hours a Day - No Problem

Reviewed on 10/23/2019Part Number: EN07-125-120T-G2AThis ELGI compressor is a workhorse. Smooth and reliable. We have it operating 12 hours a day since its installation and it has been humming along. Very happy and will definitely be working with you on proper maintenance and we will recommend the ELGI compressor to anyone and will send them your way. Thanks for the follow up.- Jody -

In and Running Great

Reviewed on 10/4/2019Part Number: EN11-125-120T-G2AWe love the compressor. It is so quiet compared to our previous piston unit and the guys love how easy it is to operate. Hardly any water in our lines. Installation was so quick. We are very happy with the ELGI compressor. Thank you very much for following up. We will tell others about Compressor World.- Christina -

Big Responsibility and It Is Doing Great

Reviewed on 9/26/2019Part Number: EN15-125-120T-G2AWe made a big investment in a new conveyor system to automate our facility requiring a compressor that would be integral to its installation. This ELGI compressor has passed every test we have put it through as we get the facility up and ready for full start up. Matt Murphy was very helpful in assuring us that the ELGI machine was the right machine for the job and so far so good. Very good experience. Thanks for following up.- Hal -

A Company That Goes Above and Beyond

Reviewed on 9/17/2019Part Number: EN05-125-60T-G2JBeing local, we had the benefit of meeting Andy in Sales in the Compressor World show room and see first hand the ELGI compressor. He was very patient in clearly understanding our needs and made us feel comfortable that this compressor was best for our keg cleaning operations. Due to a very tight spot, the unit was going to be broken down and then installed on a mezzanine above our production floor. The Compressor World installation team did an awesome job and it is set up perfectly. The start up and training went great and we are very happy with the compressor. Can't recommend them enough. Cheers!- Kenny -

We Love It

Reviewed on 9/9/2019Part Number: EN05-125-60T-G2JWent from an old, piston unit to the rotary screw and we love it. It provides all the necessary air for our shop with no problems and it is so quiet where we can actually talk to each other without shouting. Great compressor and would definitely recommend it to other auto repair shops. Appreciated the follow up.- Rick -

Fantastic Customer Support

Reviewed on 8/29/2019Part Number: EN11-125-120T-G2AHappy with the compressor but can't say enough about the customer support in making sure that we were totally satisfied with the purchase. Says a lot about your organization to go above and beyond. Will definitely recommend Compressor World to others.- David -

Great System

Reviewed on 8/16/2019Part Number: EN11-125-120T-G2AHaving an all-in-one system is great. It frees up room in our shop and nice to have such a quiet machine. Everything about the purchase went smooth and will recommend both the ELGI compressor and working with Compressor World to my neighbors. Appreciated the follow up.- John -

Well Worth the Investment

Reviewed on 8/6/2019Part Number: EN05-125-60T-G2ANeeded to upgrade due to growth and had never had a commercial grade compressor. The selection on the Compressor World website was a little overwhelming but Matt M. was great in helping us choose the best machines for our needs. The compressor is outstanding. Looks great. Nice and quiet and easy to operate. Highly recommend the ELGI compressor.- Charles -

Great Machine - Great Service

Reviewed on 7/24/2019Part Number: EN11-125-120T-G2AVery happy with the ELGI compressor. Working with Andy in Sales was great to work with. He was extremely helpful in answering all of our questions and making sure that this machine met all our needs. It is perfect for our operations. Quiet and compact. Thumbs up to the whole experience.- Mark -

Compressor Runs Great

Reviewed on 7/23/2019Part Number: EN07-125-120T-G2AVery happy with the compressor. It runs great and is easy to operate. The whole process was great. Matt M. was fantastic to work with. He was very responsive and quick in getting all the information we needed to make what we now know was a great choice. Highly recommend doing business with Compressor World and the ELGI compressor.- Nick -

A Rocky Start

Reviewed on 7/23/2019Part Number: EN05-125-60T-G2JHad to deal with a faulty motor once we got the unit installed and operational. I was surprised since it was a WEG motor, a very good brand. Once that was taken care of the compressor has been running fine. Customer service was good throughout but still a little weary on the purchase. Time will tell.- James -

It's a Dream

Reviewed on 7/1/2019Part Number: EN11-125-120T-G2AThe ELGI compressor is our first rotary screw machine and it works like a dream. Very easy to operate and it is so quiet compared to the old piston units we had. Very good experience with Compressor World and they were very good at explaining the good and bad of switching to a rotary screw. Very happy with the compressor and with the folks at Compressor World.- Kelvin -

Compressor Works Fine - Be Leary of Lead Time

Reviewed on 6/27/2019Part Number: EN11-125-120T-G2AWorking with Matt at Compressor World was great. He was very helpful in detailing the differences in the various brands and was very patient with all my questions. The machine installed easy enough and works fine. Only thing that was a problem was we were told that we would have the unit in a week and it took almost six. Not much of a problem since we used our old compressor but did disrupt our scheduling. Otherwise, very good experience with Matt and Compressor World.- Jim -

Runs Great

Reviewed on 6/26/2019Part Number: EN11-125-120T-G2AVery happy with the compressor for our operations. It was our first rotary screw compressor so we were a little hesitant on how easy it would be to operate. It's great to work with and reliable. Very happy and dealing with Compressor World was great as well. Will look to them for any additional needs that we have. Thanks for the follow up.- Rob -

Great Compressor - Great Customer Service

Reviewed on 6/26/2019Part Number: EN05-125-60T-G2AVery happy with the all in one unit that is a space saver for our small shop. Compressor runs great. Provides all the air we need. Had a minor hiccup and Compressor World was quick to have a local service tech here in no time and fix a minor problem that resulted from shipping. Very happy with overall experience and will definitely recommend dealing with Compressor World.- Abe -

Pumped Over The Compressor

Reviewed on 6/25/2019Part Number: EN05-125-60T-G2AThe compressor and dryer set up is awesome. Works great and very quiet which is needed because it sits in our open brew room which is near our tap room with our customers. Very happy with it and you guys helped out a ton. A little confused on some of the operation of the compressor and would like the owner's manual be a bit more helpful. Otherwise, will recommend the ELGI compressor and Compressor World to anyone.- Stuart -

Bit of a Learning Curve But Compressor Works Great

Reviewed on 6/19/2019Part Number: EN11-125-120T-G2AIt was the first time we went with a rotary screw compressor to run our shop and we were use to the high pressure noise of our piston unit. It take a little getting used to at first with the ELGI compressor because we weren't sure if it had the same power to operate our impact tools, sand blaster, and spray booth but it sure does. It provides more than enough pressure for our shop and it is SO quiet compared to a piston unit. Very happy with the compressor so much that we bought another one for our facility in Kansas. Great customer support from Compressor World and we definitely are a satisfied customer. Thanks so much for following up.- Dylan -

Completely Satisfied with the Compressor

Reviewed on 6/19/2019Part Number: EN07-125-120T-G2AThe ELGI compressor is great. It replaced an old piston unit and I was totally against having a new machine inside our production area but this machine is so quiet and it provides more air than what we had. The installation was simple and having an all in one system saves space and the machine looks great. Completely satisfied with the ELGI compressor and definitely recommend doing business with Compressor World.- Eric -

Very Happy with the Compressor

Reviewed on 5/22/2019Part Number: EN05-125-60T-G2AWe are very happy with the ELGI compressor for our packaging machines. It was easy to install. We like the all-on-one set up with dryer and tank taking up little space on our floor. Pleasantly surprised at how quiet it is. Dealing with Compressor World was for the most part good but one issue that we struggled with was the expected lead time did not match the actual delivery time. We needed to follow up more than we would have liked for the expected delivery which held up our operations a bit. Otherwise, very good experience.- John -

Runs Great and Looks Awesome

Reviewed on 5/15/2019Part Number: EN07-125-120T-G2AOur screen printing business is growing and we definitely outgrew our old piston unit. This ELGI compressor with dryer and tank is more than we expected and delivers all the air that our two presses require. It is a sharp looking as well and looks great in our production area and is a whisper compared to the piston unit. Had a bit of a problem early on with the machine not loading at times but Compressor World was quick to get us in touch with the ELGI service rep and everything is fine. Great experience.- Randy -

Works Great

Reviewed on 5/13/2019Part Number: EN05-125-60T-G2JWe are using the compressor paired with an additional desiccant dryer to operate our facilities very delicate controls and they work great. The total package of compressor, dryer, and tank is a space saver and the installation was a breeze. The Nano desiccant dryer and filter also is a space saver and delivers the necessary clean, dry air that we require. Very good experience with the equipment and with Compressor World.- Phil -

Great Selection

Reviewed on 5/1/2019Part Number: EN11-125-120T-G2AVery happy with the ELGI compressor. Set up was easy and it's sits in the back of the shop and we have no worries. We went with the high pressure model and it delivers what we need. Very impressed with the selection of different brands available from Compressor World but very happy with our choice of the ELGI brand. Appreciate the follow up.- Sean -

First Rotary Screw - Going Great

Reviewed on 4/29/2019Part Number: EN05-125-60T-G2AAs our business has grown, we realized we needed a much better machine than the used, piston unit we found on Craig's List. Searching on line, we knew we found experts when we came across the Compressor World website. Matt Murphy in sales was very knowledgable and patient with all the questions that we had. He stressed the quality and warranty of the ELGI compressor which was important. We are very happy with the machine and like that we can get all of our PM parts through Compressor World as well.- Brandon -

Great Machine

Reviewed on 4/4/2019Part Number: EN05-125-60T-G2JWent with the high pressure model and runs all of the machines and tools in our shop no problem. Highly recommend this ELGI compressor.- Dave -

Far Exceeded Expectations

Reviewed on 4/3/2019Part Number: EN07-125-120T-G2ACan't say enough about the ELGI compressor. It far exceeds our expectations. We needed more cfm due to new equipment and the power and efficiency of this machine is amazing. The biggest thing we have noticed is a reduction in our electric bill due to the efficiency of our system, primarily the compressor. Did have a slight error message glitch but that was handled immediately by the Compressor World service team. Highly recommend this ELGI compressor and dealing with Compressor World.- John -

Excellent Machine

Reviewed on 4/2/2019Part Number: EN11-125-120T-G2AWe need to have it operating 24 hours a day and it performs great. Love the total system of the dryer and filters in one package. Highly recommend this machine.- Eric -

Very Easy to Work With

Reviewed on 3/25/2019Part Number: EN11-125-120T-G2AThe ordering process and customer knowledge was top notch. Installation was a breeze and we love the all-in-one set up. Compressor is easy to operate and works great. Very happy with the purchase and really appreciate the follow up. Will definitely recommend you guys to everyone.- Travis Biggs -

Top Notch Experience

Reviewed on 3/20/2019Part Number: EN11-125-120T-G2AWonderful machine that performs better than expected. Great pricing and overall experience. However, need better accuracy when providing lead for machine delivery but will surely do business with again.- Joe Hirsch -

Much Better

Reviewed on 1/3/2019Part Number: EN07-125-120T-G2AMuch better than our old piston compressor, super quiet, running fine.- Food Manager -

Easy to Install

Reviewed on 1/1/2019Part Number: EN05-125-60T-G2JVery easy to purchase, the staff answered all of my questions about the compressor and helped me with the electrical. It made the installation very easy for my staff.- BodyMan -

Refreshing

Reviewed on 10/18/2018Part Number: EN05-125-60T-G2JGreat service! Matt knows his business. Refreshing to buy from good folks.- Chris -

Second to none!

Reviewed on 10/10/2018Part Number: EN11-125-120T-G2AWOW! I must say your customer service is second to none. I'm so glad I purchased from Compressor World, you have a customer for life! Thank you!- David -

Compressor works great!

Reviewed on 9/10/2018Part Number: EN11-125-120T-G2ACompressor works great!- Eric -

Brett

Reviewed on 8/20/2018Part Number: EN07-125-120T-G2AWe bought the Elgi 10 hp compressor and it is everything we expected. I have already recommended it to other furniture/ cabinet manufacturers. Quiet and economical ++- Brett -

Henry

Reviewed on 8/20/2018Part Number: EN05-125-60T-G2ATruly a 5 star rating. Machine is great and I will buy again! Henry, Florida- Henry

Need Help? Call an expert at 1-866-778-6572

We're open Mon - Fri / 8:00 AM - 5:00 PM EST